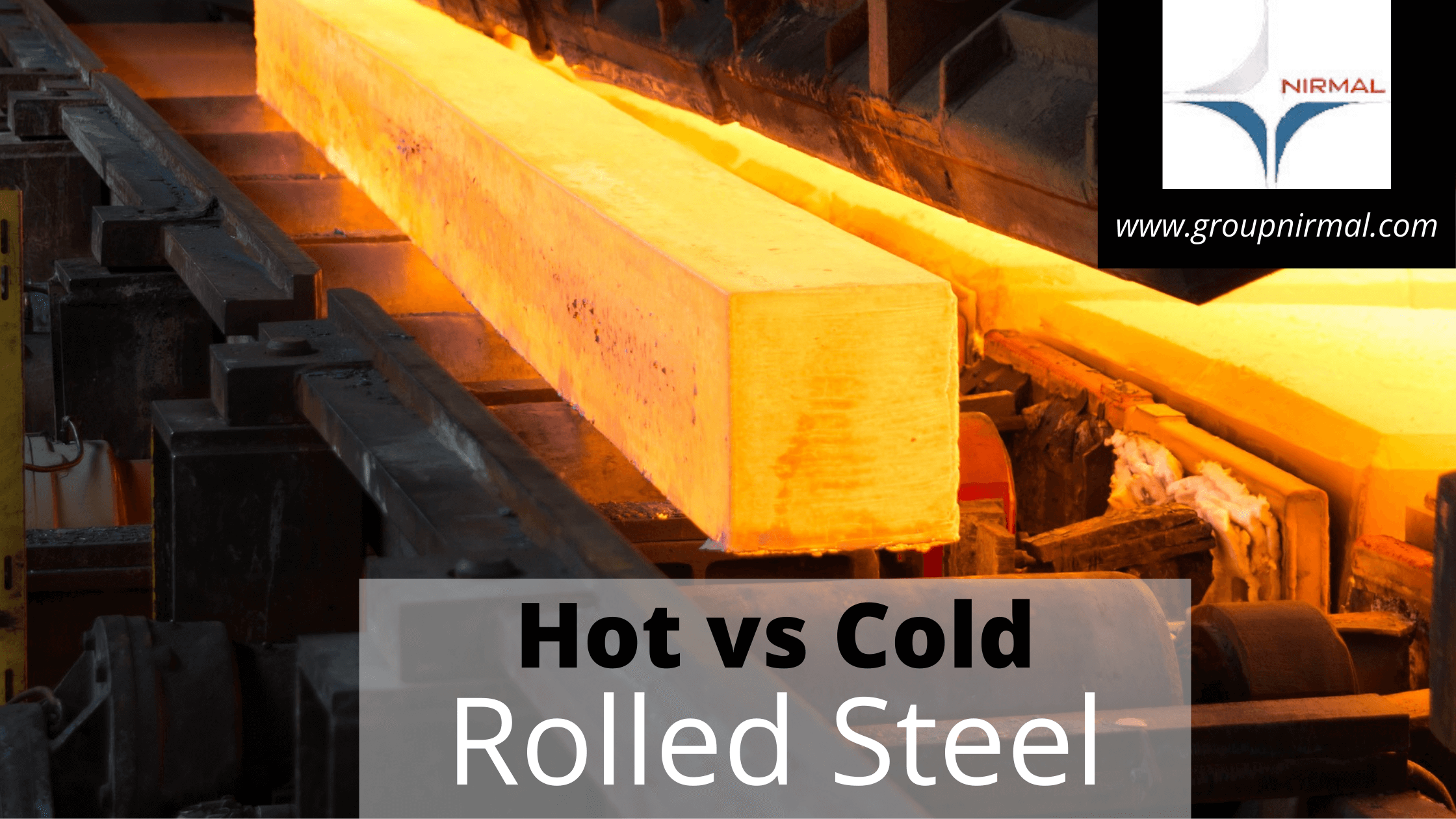

Hot rolling and cold rolling are two different processes that are used in manufacturing steel. Hot rolled steel is used in many industries, from structural components of buildings to agricultural equipment to metal buildings. On the other hand, cold-rolled steel is primarily used to manufacture household appliances, lockers, furniture, etc. Moreover, many steel pipes manufacturer often manufactures both hot-rolled and cold-rolled steel, which help several types of industries in one way or another.

As the name suggests, the hot-rolled implies the steel produced after rolling the steel at an extremely high temperature of 926°C to make the steel immensely durable in the long run. On the other hand, creating cold-rolled steel includes hot-rolled steel processed further in the cold reduction mills. The process makes the steel shinier, durable in the long run, and you can use it in all kinds of projects. Understanding the difference between the two will give you the necessary insight while purchasing.

Hot Rolled vs Cold Rolled Steel – Key Differences

Finding the difference between hot rolled and cold rolled steel is not as troublesome as you might think. Even though many spring steel wire manufacturers in Kolkata manufacture both hot-rolled and cold-rolled steel, before purchasing one or the other, you should know the difference between the two to make an informed choice. Both kinds of steel have their advantages and disadvantages; however, here is how you can tell them apart. :

1. Pricing

When you compare both hot rolled and cold rolled steel, hot rolled steel is less expensive than cold-rolled ones. This is because creating cold-rolled steel requires another step, with multiple resources to make it perfect.

2. Shapes

An excellent hot rolled steel made of quality galvanized steel wire could be shaped into any form with proper materials. From UC, UB to PFC, flats you choose from any shape of hot rolled steel you want. For cold-rolled steel, the shapes are limited to only a few, like sheets, CHS, SHS, RHS, etc.

3. Accuracy in Designs

Hot rolled steel might not come in perfect shapes most of the time because of all the heating that promotes expansion and shrinking it goes through. However, that is not the case with cold-rolled steel, as almost 99% of the cold-rolled steel products will be in perfect shapes.

4. Surface Texture

The surface texture of hot-rolled steel that has not undergone any buffing might be rough. Before using the hot-rolled steel products in any of your projects, you might want to rebuff and remove them before painting them. Most cold-rolled steel has a smooth and aesthetically pleasing surface finish, sometimes even shinier.

Conclusion –

When it comes to manufacturing furniture and other metal products like aluminum conductors, wires, etc., Group Nirmal remains of the top brands in the country. They are known for providing top-quality products that are affordable and durable in the long run. With more than two thousand customers across various industry verticals, the Group Nirmal is the best spring steel wire manufacturer in Kolkata and has managed to dig its foothold in the construction industry since its inception.