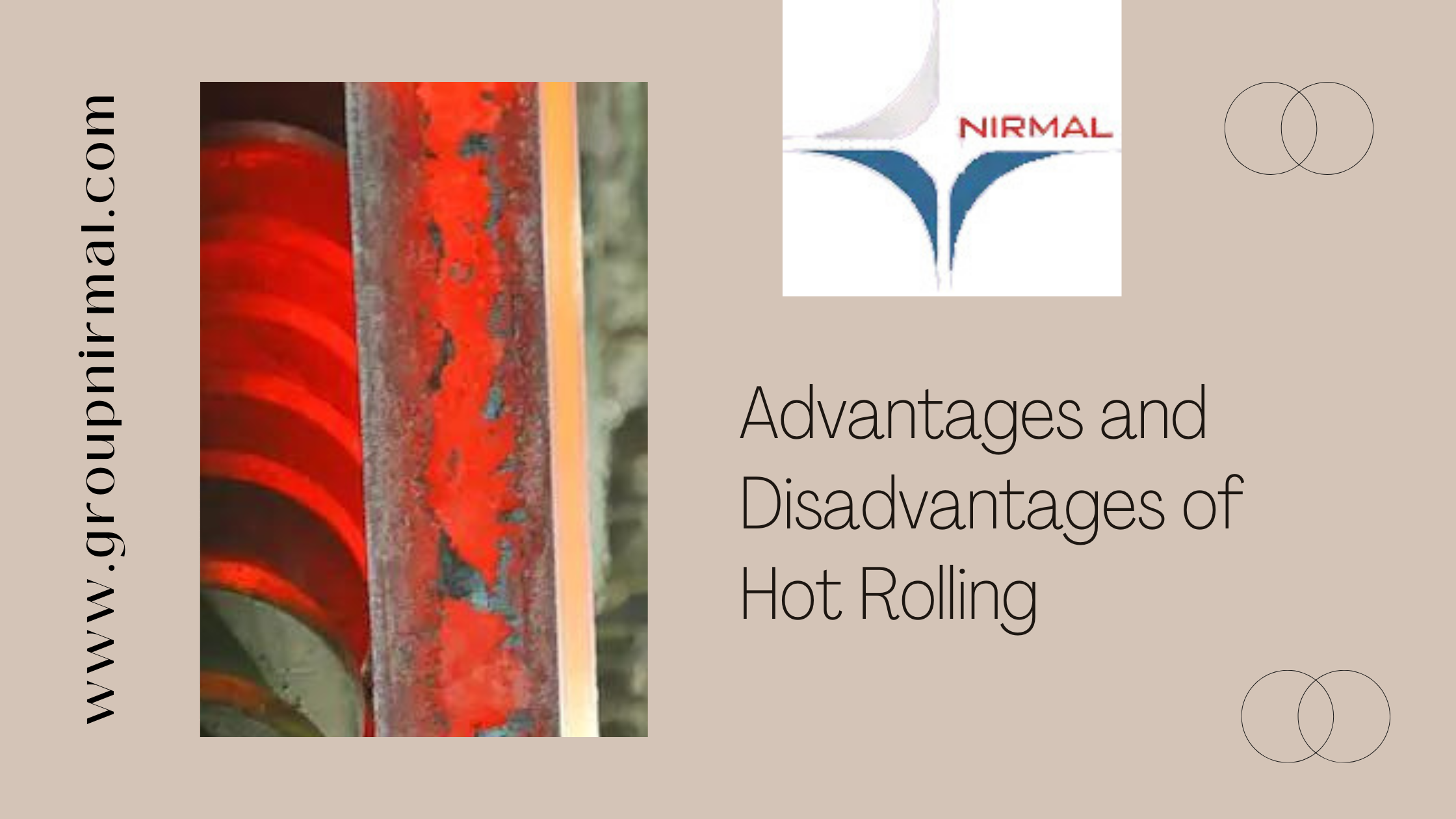

Hot rolled steel is one of the most prominent processed steel types used across several construction and fabrication industries for various reasons. Not only hot rolled steel has better formability, but it is also easier to work with hot rolled steel. Aluminum conductor steel reinforced cables are the perfect example of how hot rolling can help manufacturers create shapes with desired geometrical dimensions without reducing the metal volume.

Advantages of Hot Rolling

Improved Properties: Hot rolling provides the steel has improved properties like toughness, flexibility, and resistance to shock, which helps the stainless steel to be durable in the long run. Hot rolled steel is also easily malleable because of the high temperature, and it can be cut or formed into any shape without any issue.

Refined Grain Structure: Due to the high temperature at which the steel is rolled, the grains of the steel is converted into refined grains, changing the property of the steel. Since the grain structure of the steel is refined, it makes the hot rolled steel much stronger than the ones that are not rolled.

Impurities Distribution: The impurities in a hot rolled steel are distributed evenly so that the steel is strong through and through. When impurities like slag are stuck in one position inside the metal, it makes the steel weaker, so even distribution is essential. Hot rolling also eliminates any porosity that might be in the steel, making it even stronger in the long run.

Disadvantages of Hot Rolling

Expensive: While hot rolled steel is known for its durability and malleability, hot rolling is also an expensive process. Since it requires expert professionals, modern tools, and great skill to handle the process, hot rolled steel is pricier compared to others.

Poor Surface Finishes: Since hot rolled steel has a higher working temperature, the surface of the end product has a poor surface finish because of rapid oxidation and scale formation. In addition, the cooling process involved getting the end product causes elements to settle in rougher places, requiring another step of smoothening the products before delivery.

Maintenance of the Temperature: It is challenging to maintain the correct temperature range that will work properly throughout the process. It requires manual handling of the uniform temperature so that the steel is hot rolled to the correct temperature.

Uses of Hot Rolled Steel

If you are wondering whether hot rolled steel products are something you could benefit from, here are some industries where hot-rolled steel is used Automotive structural parts such as frames, Machine structures, Metal buildings, Agriculture equipment, etc.

Conclusion

If you want to ensure that you are working with high-quality hot-rolled steel, finding the best manufacturer is the first thing you should do. Group Nirmal is one of the leading manufacturers of hot-rolled steel in India, which has helped more than 2000 customers find their desired high-quality steel products. They utilize the latest technology and expertise of skilled professionals to ensure that their products are unparalleled and offer market-oriented products and services.