Metals have long been regarded as one of the most important driving factors of industrialization. Among all the metals used, Steel has always held a patronizing position. Steel is a raw material and intermediate product. Steel production and consumption are commonly regarded as the markers of economic success in the country. As a fact, it should not be an exaggeration to claim that the steel pipes manufacturer or any aluminum conductor manufacturer in the industrial sector has always been at the forefront of industrial progress and is the foundation of any economy.

The Development of Steel Pipes Manufacturers:

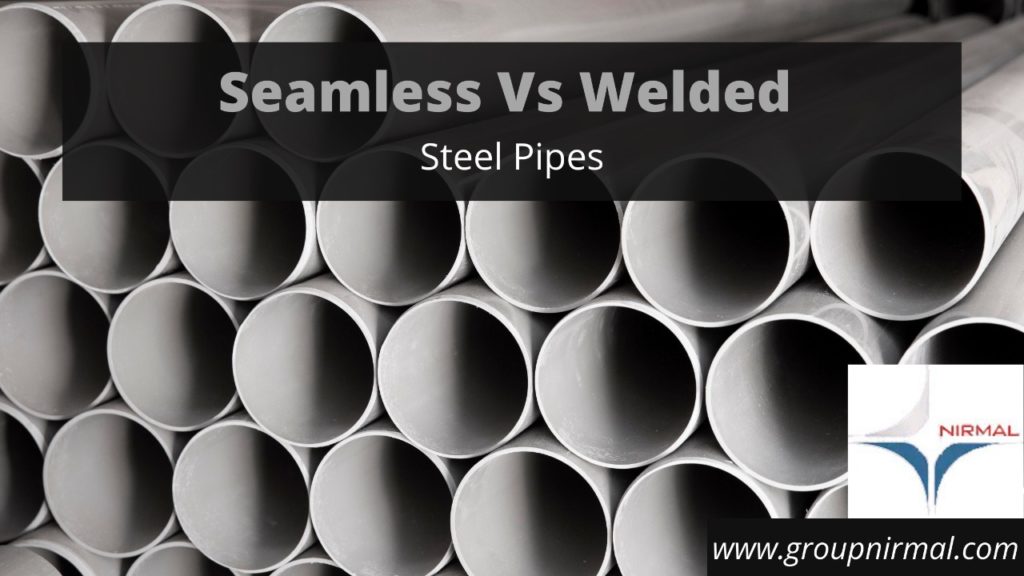

The development of steel pipes boasts nearly 100 years of rich history. In 1815, a Scottish inventor pioneered the use of steel pipes to connect tubes intending to transport gas for lighting. Later, the United Kingdom secured a patent for the extrusion method of creating seamless steel pipes in 1836. However, the German Mannesmann brothers created the process of directly producing seamless pipes from bar steel until 1885.

- While steel pipes are rigorously manufactured across the globe, India has emerged to be among the top 3 steel pipes manufacturing pioneers in the world after Europe and Japan.

- While the global steel pipe market is estimated to be around $ 90 billion and over the next 3 years is expected to grow by 4% CAGR, the Indian steel pipe industry is expected to be somewhere between Rs 50,000-55,000 Cr and is 8-9% of the global steel pipe market.

- Electric Resistance Weld Pipe (ERW) accounts for 50% of the market in terms of value.

- Stainless Steel and Submerged Arc Weld (SAW) pipes account for the remaining 50%.

- ERW pipes account for around 70% of the total volume, and stainless steel and SAW pipes account for 30%.

The domestic market for stainless steel is expected to be around 1 million tones. These pipes are well-used in applications to ensure low failure rates and long service life. Oil and gas, refineries, petrochemicals, and electricity industries are the primary end consumers of these pipes.

Challenges Faced By Steel Pipes Manufacturers:

No matter how rapidly the steel pipe industry develops, the steel pipe manufacturers are no strangers to challenges. While high raw material and energy costs along with overcapacity and price volatility make the foremost challenges, here are a few other challenges faced by these manufacturers:

1. The rising cost of metal workpieces indicates that squandered materials significantly cut into revenues. Along with this, the competitive landscape is also reducing margins in many operations.

2. The complex manufacturing process of steel pipes and tubes goes through several stages and uses a multitude of tools from the beginning to the end. During this process, a multitude of fluids are required, and some of which can only be used during the forming stage, and other specialty colorants and fluids can only be used in the welding or cutting phases of production. Many times, costs are included, but the fluids are wanted after use.

3. The financial liabilities increase while investing in technology upgrades.

4. The COVID-19 situation has also contributed to the challenges faced by every steel pipes manufacturer.