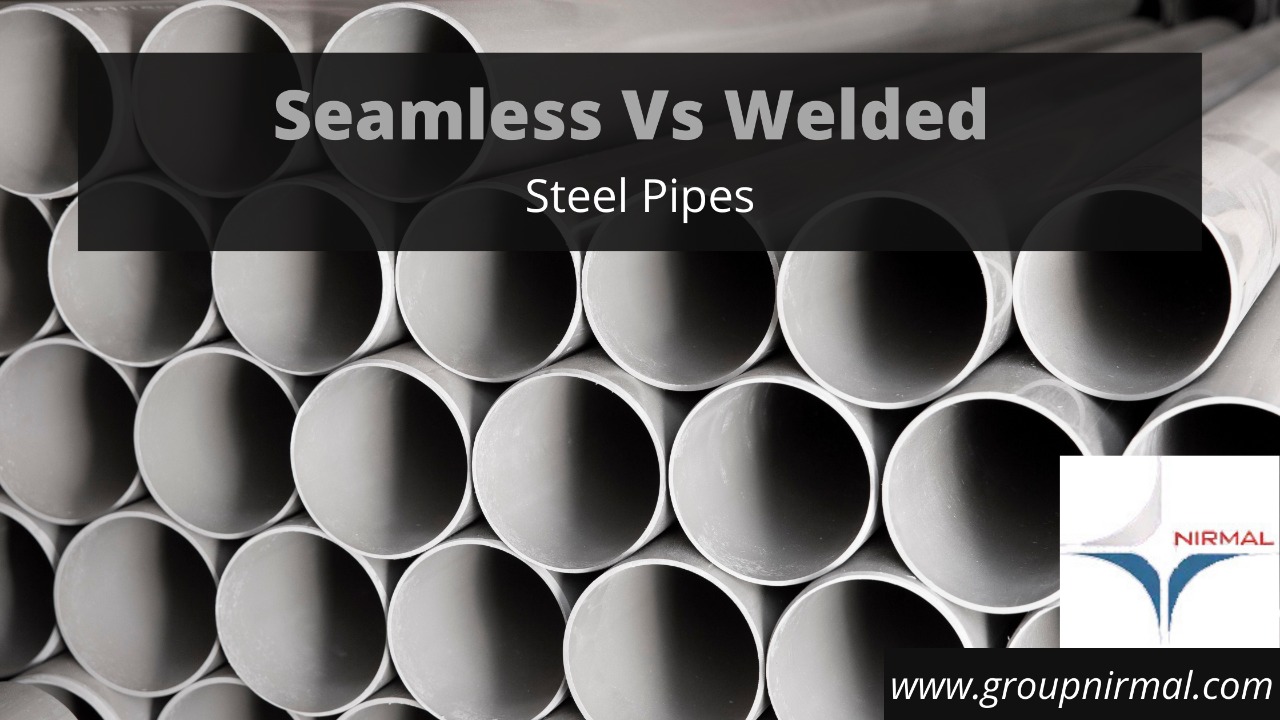

Seamless and Welded pipes are often confused with each other, which is why the comparison on Seamless Pipe vs Welded Pipe mentioned below can help you distinguish between them better.

Seamless Pipe vs Welded Pipe: Differences

1. Nature of Making

There is no better option than the seamless variety when it comes to steel pipes, as it has no gaps on the surface. On the other hand, welded steel strips or plates bent and twisted into square or round shapes before being welded together make steel pipes have gaps on the surface. Also, the surface quality of seamless pipes is rough compared to the smoother surface quality of welded pipes.

2. Characteristic Difference

The maximum diameter of a seamless steel pipe is 650mm, and the smallest diameter is 0.3mm. Seamless steel pipes have a lesser chance of getting affected by corrosion as it has corrosive-resistant qualities. Similarly, it has highly intensive strength and can withstand a good amount of pressure.

Welded pipes are considered to withstand 20% less burden in comparison, and having no generic size restriction, it can be done as per the requirement. T-welded steel pipes offer excellent corrosion resistance when nickel is added to the weld. The higher the Ni content in T-welded steel pipes, the better the corrosion resistance in sulfuric or hydrochloric acid conditions. Corrosion may be prevented in most cases by simply adding Cr to the T-welded steel pipe. If not done, weld areas get more prone to corrosive attacks.

3. Purpose

Both pipes hold different purposes. Seamless steel pipes can be found in a wide range of applications, from oil and gas exploration and drilling to the construction of automobiles as well as the manufacturing of tractors and planes.

For oil drilling and machinery manufacturing, electric welded steel pipes are used; furnace welded pipes can be used as water pipes, and large-diameter welded l pipes can be used for slightly elevated oil and gas transportation; spiral welded pipes are used for oil and fuel transportation, steel pipe piles, overhead bridge piers, and other applications.

4. Manufacturing Process

There are manufacturing differences as well when talking about seamless pipe vs welded pipe. While seamless steel pipes undergo a complex and lengthy manufacturing process, the welded pipes are done in a shorter time, experiencing a simple process. Also, this process automatically makes the former’s making costlier than the latter.

5. Checking of the Interior Surface

Seamless steel pipes, unfortunately, do not have the benefit of having an internal surface check, unlike welded steel pipes, whose interiors can be examined before their manufacturing process can begin.

6. Suitability

Seamless steel pipes are manufactured in such a way to be highly suitable for high-pressure and corrosive environments. And welded steel pipes are generally suited for environments that are less corrosive in nature, having low pressure.

Conclusion

Whatever be the differences between the two, the best quality products can only be provided by Group Nirmal. From producing the best aluminum conductors, wires, and construction steel items, Group Nirmal is deemed to be the best steel pipes manufacturer in town.