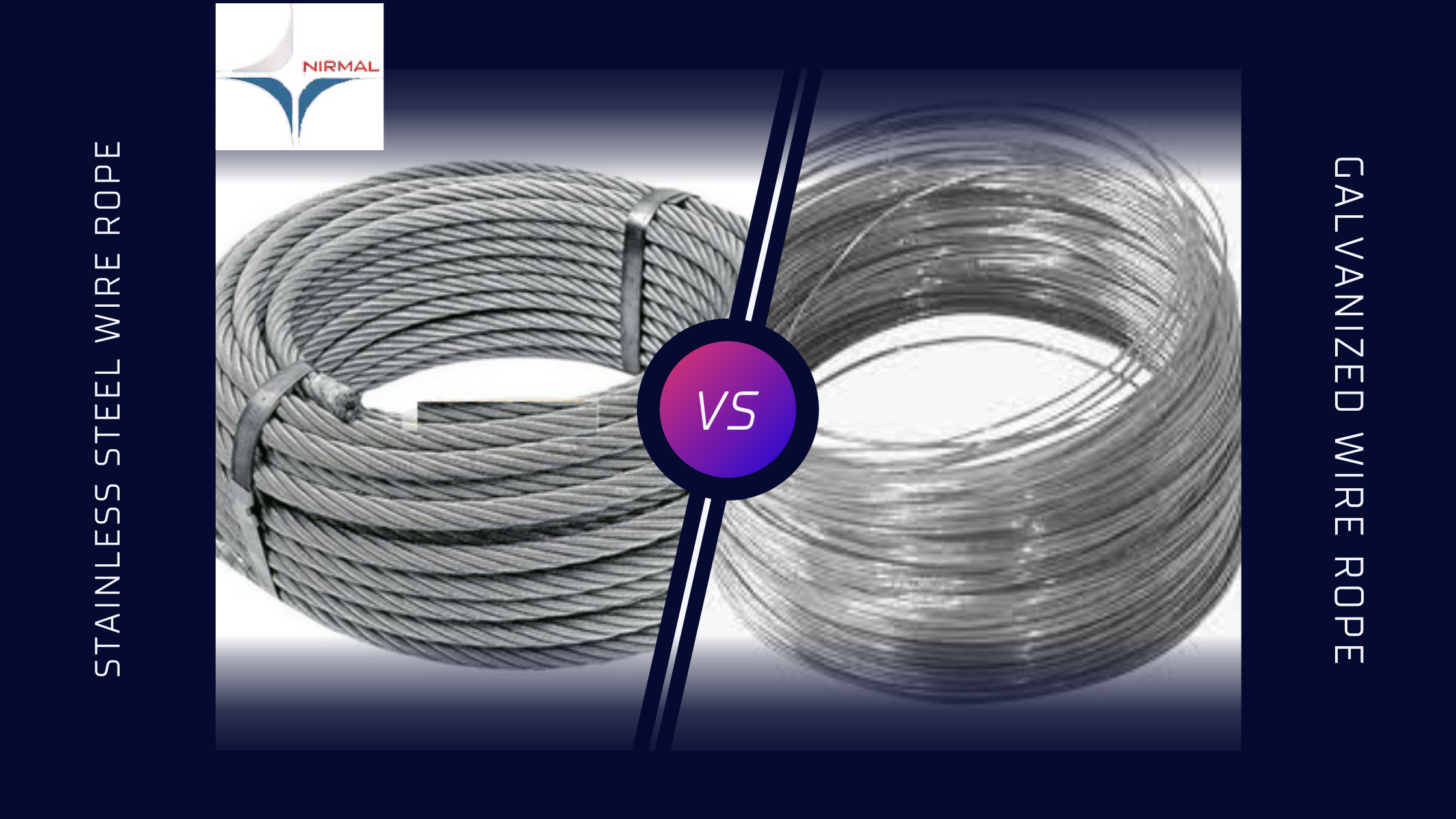

Wire ropes are a common tool, often considered a machine, and have many applications. Each type of rope is used for specific tasks and varies in strength, flexibility, abrasion resistance, etc.

Wire ropes are available in two types – galvanized wire rope and stainless steel wire rope.

What is Galvanized Wire?

Galvanized wire rope is a steel write rope with a layer of zinc, which helps in preventing the ropes from corrosion and rusting. Mostly suitable for construction in wet places, these wire ropes prevent the deposition of dust in the inner steel.

Galvanized wire ropes shouldn’t be used in or around salty seawater, or with anything to do with food or chemical products.

What is Stainless Steel Wire?

Stainless steel wires are very common in industrial and commercial industries and offer a decent degree of protection against corrosion and rust. Most often used in indoor applications, stainless steel will not do good in outdoors as it does in indoor usage.

Differential Points: Strengths, Durability, Process, Price, Uses.

Strengths

Galvanized wire rope is not as strong as a stainless steel wire rope

Durability

With time, galvanized wire rope coatings will wear off, but may still be resistant to chemicals or rust. Stainless steel wire rope is highly resistant to corrosion, or harsh chemicals.

Process

Stainless steel wire rope is made using standard alloy used in ropes or cables, whereas, galvanized wire ropes are steel wires that have gone through the galvanization process.

Price

The price of both types of ropes are around the same, however, stainless steel wire rope is often a bit costlier than the galvanized wires.

Uses

Galvanized wire ropes are suitable for marine locations and constructions around them. Objects or constructions around these locations are exposed to wetness and dampness at all times.

Stainless steel wire ropes are used in various industries including, commercial, manufacturing, etc.

Galvanized Wire Advantages

- Galvanized wire ropes are cheaper, and more cost-effective, especially in the case of rigging applications. It is easy to use or install, and also requires lower maintenance than most other types of ropes.

- Galvanized wire ropes are easy to work with, as they can be played in shape easily.

- Galvanized wire ropes are lighter in weight especially compared to stainless steel wire ropes.

Stainless Steel Wire Advantages

- Stainless steel wire ropes offer high resistance to corrosion and are often higher than many other types of rope with lower alloys. Stainless steel wire ropes can stay durable even in harsh environments with alkaline, chlorine, etc.

- Stainless steel wire ropes are so strong that they can withstand even the hottest and coldest temperatures, making them suitable for cryogenic settings.

- Stainless steel wire ropes are durable even with a single layer of coating, and they will have a years-long lifespan.

- Stainless steel wire ropes require low maintenance, making them easier to upkeep. It is also recyclable.

- Stainless steel wire ropes are highly flexible, and you can easily shape them according to your uses and requirements using machinery like hydraulic press, hand swaging, etc.

Conclusion

Do you have a construction business, and you are wondering what type of rope will work best for you? Well, who other than stainless steel pipe suppliers like Group Nirmal can help with expertise and knowledge? Group Nirmal is a steel pipe manufacturer based in Kolkata and is a leading group in the infrastructure space.