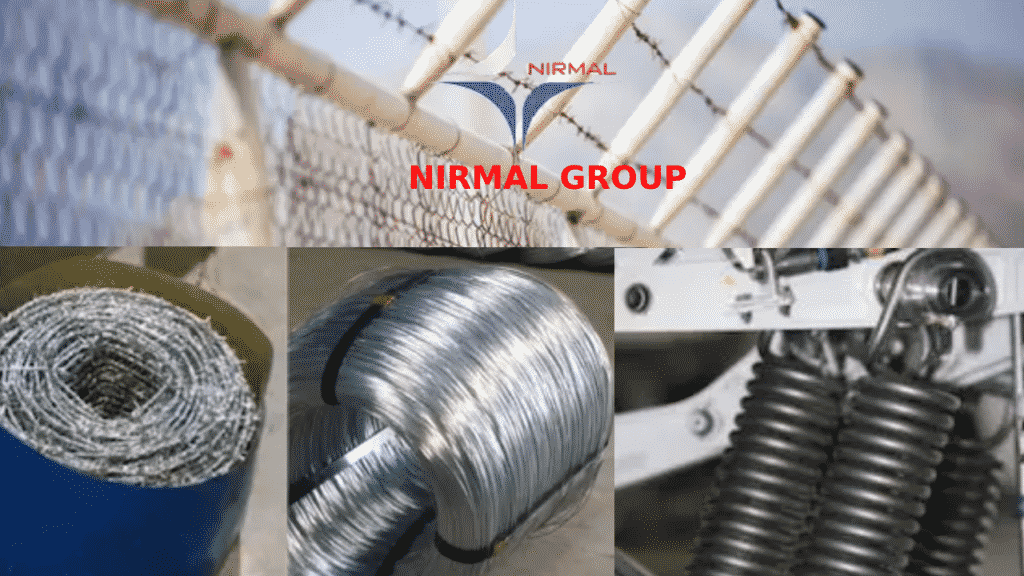

With tremendous experience and goodwill in the market, Group Nirmal is a spring steel wire manufacturer in Kolkata. In-depth knowledge and expertise are what make us unique from others. Our team is work-oriented and Professional. We guarantee that our products are affordable as well as of top quality. We believe in delivering quality over quantity.

Spring Steel Wire

Group Nirmal is a reputed spring steel wire manufacturer. Spring steel is a name given to a wide range of steel which is generally low-alloy manganese, medium-carbon steel, or high-carbon steel.

They have very high yield strength. Objects made of spring steel can return to their original shape despite deflection or twisting.

Spring Steel Wires are used for manufacturing industrial suspension applications, springs, prominently in automobiles and tension and compression coil.

Manufacturing

- To convert steel to spring steel, the steel is shaped to the desired spring shape.

- It is then heated red hot until it loses its attraction for a magnet.

- It is further quenched in a suitable liquid generally water, brine, or oil.

Design

- The standard diameter of the steel spring wire ranges from 0.02mm to 12.0mm.

- Their thickness may vary from 2mm to 6 mm.

- They can be manufactured with high carbon steel or stainless steel as well.

- Weight may differ from 5kg to 1000kg.

- The packaging is done with the coil.

- To prevent them from rusting oil is applied to them.

Utilization of Spring Steel Wire

Spring steel wire finds application in

- diverse fields ranging from the automotive industry, mattress springs, springs, spring washer, chain bush, tiller spring, shims, saw blades, lock picks, antennas, binder clips, leaf springs, and s-tines, scraper, and several others.

- These wires are also used as piano wires.

- Used extensively in the manufacturing of metal swords for stage combat because of their resistance to bending and shattering.

- One of their application is in knife manufacturing.

Benefits of Using Spring Steel Wire Over Any Other Variant

- A general-purpose spring wire is heat resistance and corrosion-resistant. Alloy spring steel wire with 10 percent or more chromium provides better corrosion resistance than other alloys or plain steel wires. Spring steel wires commonly use precipitation and austenitic hardening.

- Spring steel wire can be easily hardened and tempered to increase elasticity and resist deformation which is not possible for other steel wires.

- Pliability and resilience is a chief characteristic.

- Spring steel wires can be galvanized or phosphatized according to the purpose of consumers.