GI wire, also known as galvanized iron wire, is a type of wire made by coating a carbon steel wire with zinc. The zinc coating acts as a barrier to protect the steel wire from rust and corrosion. The process of applying the zinc coating is called galvanization, which is why it is called galvanized iron wire. This wire is commonly used in construction, industrial applications, and as a material for nails, wire mesh, wire ropes, barbed wire, and chain link fencing. It is also used in overhead electrical transmission and distribution lines.

How to Make Gi Wire?

The process of making GI wire involves several steps:

- Steel wire is made using a wire drawing process, where steel is passed through a series of dies to reduce its diameter and increase its strength.

- The steel wire is then cleaned and pickled to remove any impurities and oxide layers on its surface.

- The wire is then dipped into a bath of molten zinc. The zinc adheres to the steel wire and forms a coating around it.

- The coated wire is then cooled and passivated, which involves immersing the wire in a solution to create a protective layer on the zinc coating.

- The wire is then wound onto spools and packaged for shipping.

- After production, the wire is tested for its zinc coating thickness, tensile strength and elongation.

The thickness of the zinc coating can be adjusted to suit the intended application and environment, as thicker coatings provide better corrosion resistance.

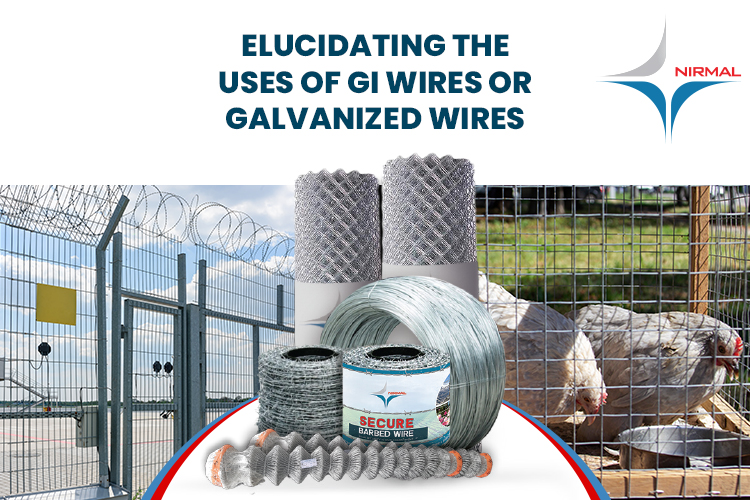

Uses of GI Wires

Galvanized iron (GI) wires are commonly used in construction and industrial applications, particularly in the reinforcement of concrete structures. They are also used in the manufacturing of wire mesh, nails, and wire ropes. Additionally, GI wires can be used in overhead electrical transmission and distribution lines as well as in the production of barbed wire and chain link fencing. They are known for their corrosion resistance and durability.

GI wire is commonly used in construction for several purposes such as:

1: GI Wire in Reinforcement of Concrete Structures:

GI wire is commonly used in the reinforcement of concrete structures. The process of reinforcing concrete with GI wire is called wire mesh reinforcement or welded wire reinforcement (WWR). The wire is used to create a mesh pattern that is embedded in the concrete to provide additional strength and stability. The use of GI wire reinforcement in concrete structures offers several benefits such as:

- Increased strength and load bearing capacity: The wire mesh helps distribute stress evenly throughout the concrete, allowing it to bear greater loads without cracking or breaking.

- Improved durability: The zinc coating on the GI wire provides protection against corrosion and rust, making the reinforced concrete more durable and long-lasting.

- Reduced cracking: The wire mesh helps hold the concrete together, reducing the likelihood of cracking under stress.

- Increased flexibility: The wire mesh allows the concrete to flex slightly, which can help reduce the likelihood of cracking or breaking under stress.

- Cost-effective: Reinforcing concrete with wire mesh is less expensive than using other types of reinforcement such as rebar.

- Easy to install: Wire mesh is easy to cut, bend, and shape, making it easy to install and adjust as needed.

Overall, the use of GI wire in the reinforcement of concrete structures can significantly improve the strength and durability of the concrete and help to extend the service life of the structure.

2: GI Wire in Tie Wire

GI wire is commonly used as tie wire in construction to secure rebar and other reinforcing materials in place before the concrete is poured. The process of using tie wire is called tying, and it’s an important step in reinforcing concrete. The use of tie wire offers several benefits such as:

- Securing reinforcement: The tie wire helps to hold the rebar and other reinforcing materials in place, ensuring that they are properly positioned and spaced to provide maximum strength and stability.

- Maintaining alignment: The tie wire helps to keep the rebar and other reinforcing materials aligned, ensuring that they are parallel and evenly spaced.

- Preventing movement: The tie wire helps to prevent the rebar and other reinforcing materials from moving or shifting during the pouring and curing of the concrete.

- Easy to use: Tie wire is easy to use and handle, it can be bent, twisted, and cut easily to fit the specific needs of the construction project.

- Cost-effective: Tie wire is a cost-effective solution for securing reinforcement, it’s cheaper than other binding methods such as welding.

- Durable: The zinc coating on the GI wire provides protection against corrosion and rust, making the tie wire more durable and long-lasting.

The use of tie wire helps to ensure that the reinforcement is properly secured and positioned, which can help to increase the strength and stability of the concrete structure.

3: GI Wire in Barbed Wire Fencing

GI wire is commonly used in the construction of barbed wire fencing. Barbed wire fencing is a type of fencing that is used for security and boundary marking, it’s made by attaching sharp barbs to a wire, usually GI wire. The use of barbed wire fencing offers several benefits such as:

- Security: Barbed wire fencing is an effective barrier that can deter intruders and prevent unauthorized access.

- Boundary marking: Barbed wire fencing is an effective way to mark the boundaries of a property or a restricted area.

- Animal control: Barbed wire fencing is often used to keep animals such as cattle and sheep in a designated area.

- Cost-effective: Barbed wire fencing is a cost-effective solution for security and boundary marking, it’s cheaper than other types of fencing such as chain link or wood.

- Easy to install: Barbed wire fencing is relatively easy to install, it can be strung between posts or attached to existing structures.

- Durable: The zinc coating on the GI wire provides protection against corrosion and rust, making the barbed wire fencing more durable and long-lasting.

- Flexible: Barbed wire fencing can be easily bent and shaped to fit different terrains or structures.

The use of barbed wire fencing can provide an effective barrier to help secure a property or restricted area, and it’s also a cost-effective solution for animal control.

4: GI Wire in Chain Link Fencing

GI wire is commonly used in the construction of chain link fencing, which is a type of fencing that is commonly used for security and boundary marking. Chain link fencing is made by weaving a series of interlocking steel wire loops, usually GI wire, together to form a mesh. The use of chain link fencing offers several benefits such as:

- Security: Chain link fencing provides an effective barrier that can deter intruders and prevent unauthorized access.

- Boundary marking: Chain link fencing can be used to mark the boundaries of a property or a restricted area.

- Animal control: Chain link fencing can be used to keep animals such as dogs and cats inside a designated area.

- Cost-effective: Chain link fencing is a cost-effective solution for security and boundary marking, it’s cheaper than other types of fencing such as wood or vinyl.

- Easy to install: Chain link fencing is relatively easy to install, it can be strung between posts or attached to existing structures.

- Durable: The zinc coating on the GI wire provides protection against corrosion and rust, making the chain link fencing more durable and long-lasting.

- Flexible: Chain link fencing can be easily bent and shaped to fit different terrains or structures.

- Transparent: Chain link fencing is transparent which makes it an ideal solution for security purposes where visibility is important.

The use of chain link fencing provides an effective barrier for security and boundary marking, and it’s also a cost-effective solution for animal control. Additionally, it’s transparent nature makes it ideal for security purposes where visibility is important.

5: GI Wire in Nails

GI wire is commonly used in the production of nails, which are small, pointed fasteners that are used to join wood and other materials together. GI wire nails are made by cutting and shaping the wire into the desired shape and then sharpening the point of the nail. The use of GI wire nails offers several benefits such as:

- Durability: GI wire nails are more durable and long-lasting than other types of nails because of the zinc coating on the wire, which provides protection against corrosion and rust.

- Strength: GI wire nails are strong and can hold materials together securely.

- Cost-effective: GI wire nails are a cost-effective solution for joining wood and other materials together.

- Easy to use: GI wire nails are easy to use, they can be driven into wood and other materials using a hammer or nail gun.

- Variety of sizes: GI wire nails come in a variety of sizes, which makes them suitable for different types of construction projects.

- Variety of finishes: GI wire nails come in different finishes such as Hot Dip Galvanized, Electro Galvanized and Bright Finish.

The use of GI wire nails can provide a strong and durable connection between wood and other materials, they are easy to use and come in a variety of sizes and finishes which makes them a suitable choice for various construction projects.

6: GI Wire in Wire Mesh

GI wire is commonly used in the production of wire mesh, which is a grid of interconnected wires that are used in construction and industrial applications. Wire mesh can be made from various types of wire, including GI wire, and it is used in a wide range of applications such as:

- Plastering: wire mesh is used as a reinforcement in plastering, to provide additional strength and stability to the plaster.

- False Ceiling: wire mesh is used as a reinforcement in false ceilings, to provide additional strength and stability to the ceiling.

- Partition: wire mesh is used as a reinforcement in partitions, to provide additional strength and stability to the partition.

- Concrete Reinforcement: wire mesh is used as a reinforcement in concrete, to provide additional strength and stability to the concrete.

- Filter: wire mesh is used as a filter in various industries such as mining, oil and gas and food processing.

- Animal Cages: wire mesh is used to make animal cages, to provide a safe and secure environment for the animals.

- Ventilation: wire mesh is used as a ventilation in various industrial and commercial buildings.

- Decoration: wire mesh can be used as a decorative element in architectural designs and interiors.

The use of wire mesh made from GI wire provides strength, stability, and corrosion resistance which makes it suitable for various construction and industrial applications. Also, the variety of wire mesh shapes, sizes and finishes makes it versatile and adaptable to different needs.

7: GI Wire in Cable Trays

GI wire is commonly used in the production of cable trays, which are used to support and organize electrical and telecommunication cables. Cable trays are made by welding or fastening GI wire in a specific pattern to create a tray-like structure that can hold the cables. The use of cable trays offers several benefits such as:

- Cable organization: Cable trays provide a structured and organized way to support and route cables, which can help to reduce clutter and improve the appearance of the installation.

- Cable protection: Cable trays provide protection for the cables by keeping them off the ground and away from potential hazards such as water, chemicals and physical damage.

- Cable ventilation: Cable trays have a certain degree of ventilation which can help to dissipate heat and reduce the risk of fire.

- Easy installation: Cable trays are relatively easy to install, they can be hung from ceilings, walls or attached to existing structures.

- Cost-effective: Cable trays are a cost-effective solution for supporting and organizing cables, it’s cheaper than other types of support systems such as conduit.

- Durable: The zinc coating on the GI wire provides protection against corrosion and rust, making the cable trays more durable and long-lasting.

- Flexible: Cable trays can be easily bent and shaped to fit different terrains or structures.

The use of cable trays made from GI wire provides a structured and organized way to support and route cables, protection for the cables and also it’s a cost-effective solution. Additionally, it’s easy to install, durable and flexible which makes it suitable for various electrical and telecommunication wiring.

8: GI Wire in Scaffolding

GI wire is commonly used in the production of scaffolding, which is a temporary structure used to support workers and materials during construction. Scaffolding is usually made from a combination of materials such as metal pipes and GI wire mesh. The use of scaffolding offers several benefits such as:

- Access to elevated areas: Scaffolding provides a safe and stable platform for workers to access elevated areas during construction.

- Supporting materials: Scaffolding can be used to support materials such as bricks, concrete, and roofing tiles during construction.

- Safety: Scaffolding provides a safer working environment for workers by reducing the risk of falls and other accidents.

- Easy assembly and disassembly: Scaffolding can be easily assembled and disassembled, making it a suitable choice for projects that require frequent movement or relocation.

- Cost-effective: Scaffolding is a cost-effective solution for providing access to elevated areas during construction.

- Durable: The zinc coating on the GI wire provides protection against corrosion and rust, making the scaffolding more durable and long-lasting.

- Flexible: Scaffolding can be easily bent and shaped to fit different terrains or structures.

The use of scaffolding made from GI wire provides a safe and stable platform for workers to access elevated areas during construction, and also, it’s a cost-effective solution. Additionally, it’s easy to assemble and disassemble, durable and flexible which makes it suitable for various construction projects.

Why Buy GI wire from Group Nirmal?

- Quality: Group Nirmal provides high-quality GI wire that meets industry standards. They provide certificates of compliance and test reports to prove the quality of their products.

- Selection: Group Nirmal has a wide range of GI wire products available in various sizes, thicknesses, and finishes to meet different construction and industrial needs.

- Competitive Pricing: Group Nirmal provides competitive pricing on their products, and can be able to offer discounts for large orders.

- Fast Delivery: Group Nirmal has a good delivery system to deliver the product on time, that is essential for construction projects.

- Good Customer Service: Group Nirmal has a good customer service team that can answer any questions you may have and provide assistance if any issues arise.

- Stock Availability: Group Nirmal has a good stock availability, to meet the customer’s needs at any time.

- Brand Reputation: Group Nirmal has a good brand reputation, which is built on providing high-quality products and excellent customer service.

Ultimately, when choosing a supplier for your GI wire needs, it’s important to research different options and compare prices, quality and service to find the best fit for your specific needs.